BIGGEST Insulated Concrete Form (ICF) in the Industry

The Nudura® standard block measures 8' long by 18" high, a huge 12 square feet. Compare that with other blocks measuring just 4' long by 16" high, a mere 5.33 square feet or others at only 4 square feet. Our standard Nudura block provides an Effective R23.59 wall assembly. Third party testing found here

When you can place up to 300% more block than your competition, that's more $$$ in your back pocket.

AND, a longer block reduces waste by about 50%. Why? Suppose you need a 3' length of block: with a standard block, you cut off 3' and 1' is garbage. With Nudura®, you cut off 3' and have 5' left. ZERO garbage.

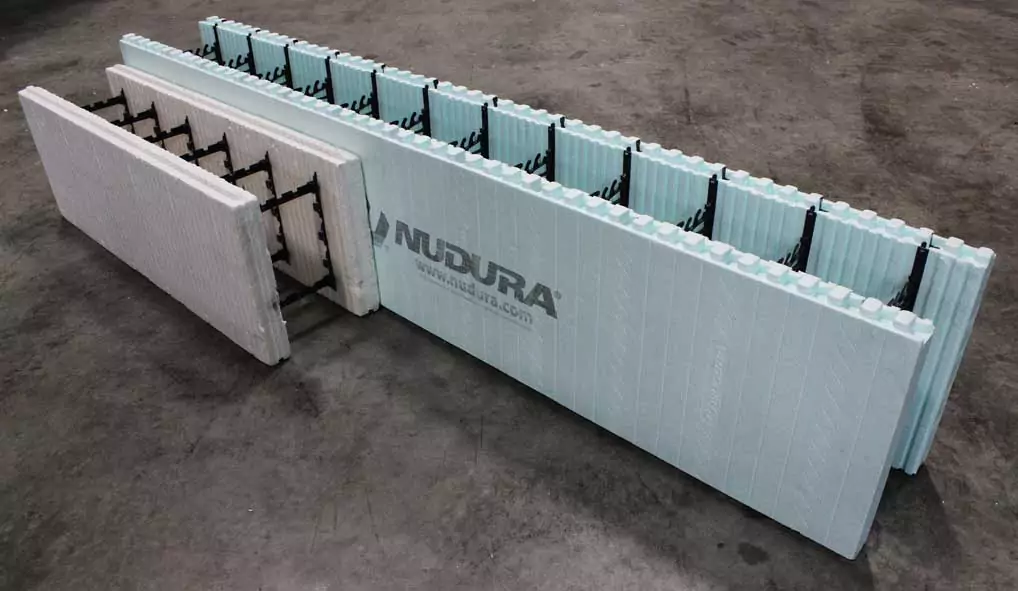

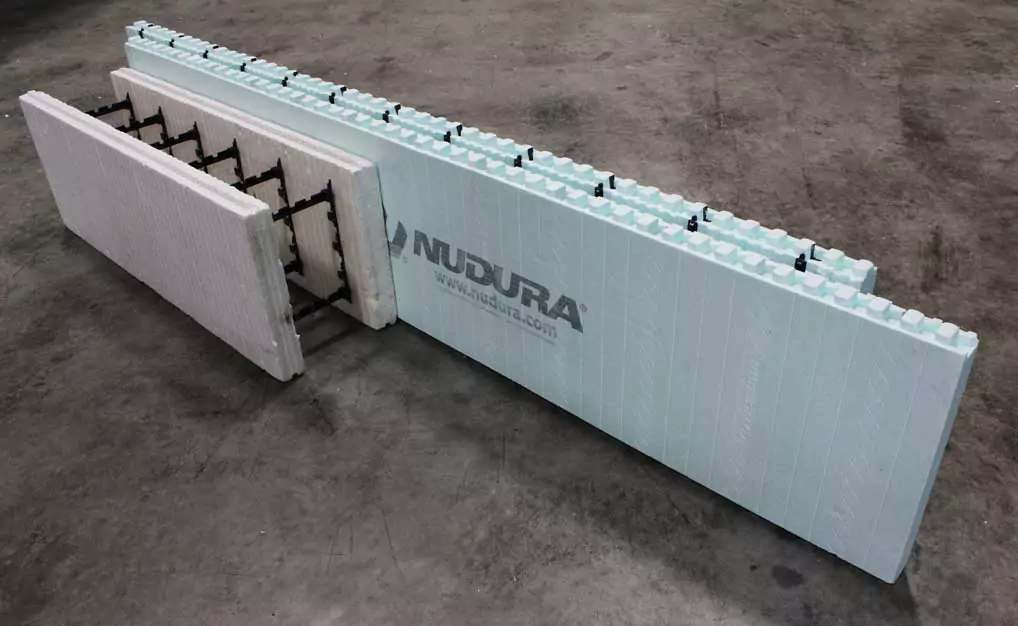

Thinnest Block in the Industry

Nudura® folding technology means thin. A typical 8" ICF takes up just over 13" of space. A Nudura® folded 8" block takes up less than 6" of width, over 50% space saving.

So what does thinness mean to you, the builder? First, as ICF delivery cost is always based on volume, the Nudura® volume results in lower delivery costs to your jobsite. Second, 50% less storage space on your jobsite improves site logistics, a big advantage on small city lots.

Thinnest Corner in the Industry

Nudura® folding technology even works on corners. A typical 8" corner takes up just over 13" of space. A Nudura® folded 8" corner takes up less than 6" of width, over 50% space savings.

So what does thinness mean to you, the builder? First, as ICF deliveries are always based on volume, this smaller volume results in lower delivery costs to your jobsite. Second, 50% less storage space on your jobsite improves site logistics, a big advantage on small city lots.

4-Way Reversible

With Nudura® there is no top, no bottom, no left and no right. The Nudura® interlock allows the block to be placed in any direction: a huge improvement to blocks with different top and bottom interlocks. The white block below has a non-reversible interlock.

What does this mean to you, the contractor? If you cut the block in half, you use the other half, reducing material costs in half and minimizing wasteage.

As Nudura® corners are reversible, you no longer need to stock left and right hand corners. Again additional savings to you the contractor.

No Form Uplift

When filling forms with concrete, form uplift occurs when concrete pressure gets between the blocks causing the forms to separate and lift. In the photo below, you can see the pair of double barbs (Duralok®) that snap across each other upon assembly and are very difficult to separate, preventing form uplift.

For you, the builder, this eliminates one more potential jobsite hastle.

No Form Settlement

It is a quiet secret in the ICF industry that the heat of hydration of the concrete can lead to reduced compressive strength of the EPS foam. This in turn leads to form settlement and the resulting shrinkage of top of wall height.

Nudura® is the only block in the industry where the polypropylene webs actually interlock and press against each other completely with a flat surface area. In the picture below Nudura® is on the left with a competing block on the right. The foam has been removed in each case to expose the web.

The block on the right has 1 3/4" gap between the two webs which can lead to form settlement under the heat of concrete hydration.

For you the builder, this means your 12' Nudura® wall will remain exactly 12' after the concrete has cured.

Continuous Fastening Strip

In the photo above, the Nudura® block is on the left, a competing block (white) on the right. With Nudura® the fastening strip runs the full height of the block; whereas with the block on the right, there is a 1 3/4" gap between each fastening web.

If you're a drywaller or a rain screen installer you'll appreciate having a Nudura® attachment area that runs continuously the full height of the wall 8" on centre, just like a wood stud.