Nudura® Monopour Project

An insulated concrete form (ICF) Monopour foundation was recently poured in White Rock by Vern Perry of Oceano Construction for owner/builder Brian Evans. In the video above Brian discusses the merits of Nudura® and the ICF Monopour System.

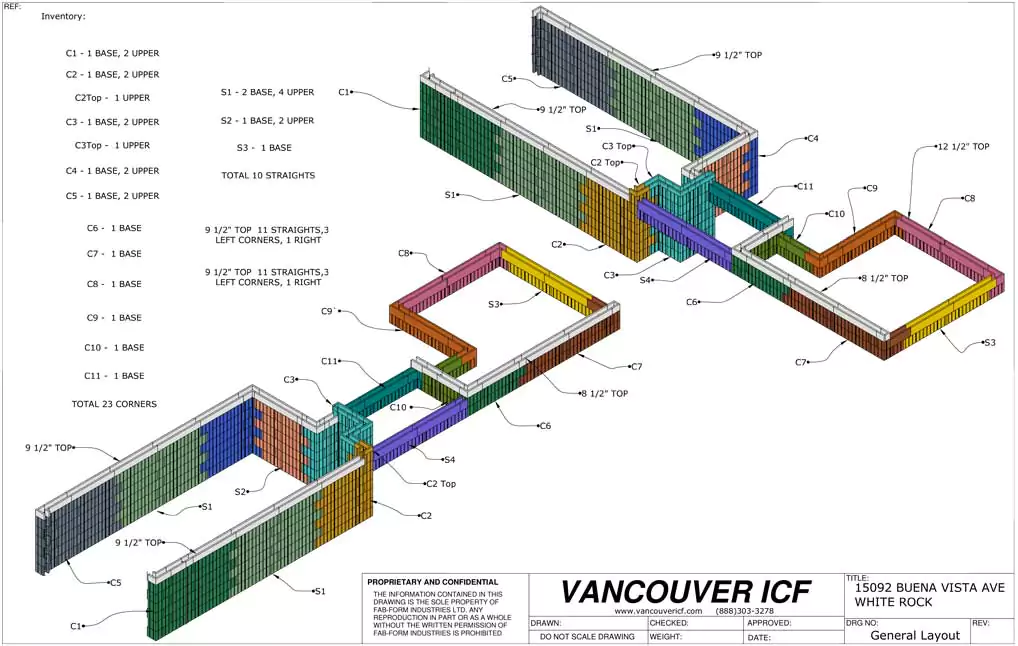

This isometric drawing of the ICF foundation and crawlspace provides the general layout of the panels which was used by Oceano Construction when installing the panels.

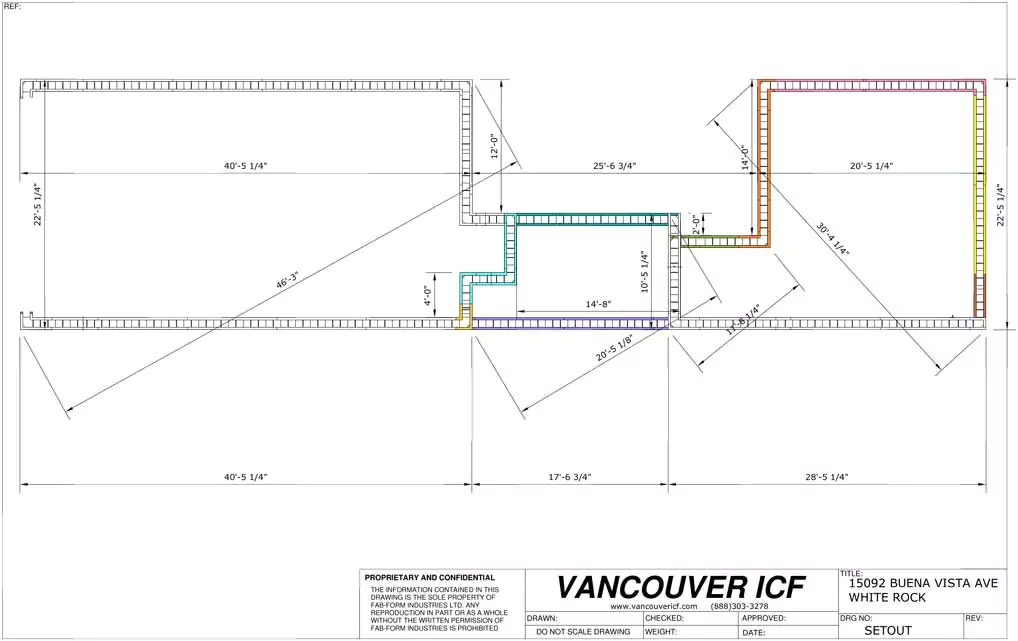

This plan drawing of the ICF foundation and crawlspace provides the diagonal dimensions of the panels used for the final alignment of the wall panels.

The excavation was dug on three levels: the full basement is closest, a secondary level and finally the crawl space level. Height difference was 7'-3" between the three levels. Notice that the builder has installed a drainage layer on the surface of each elevation to prevent water buildup behind the footings and to minimize water wicking up into the footings.

The batter boards to align the MP panels can be seen on each corner. The first delivery was the panels for the full height foundation.

The second delivery was for the stem wall panels. The full height walls were installed first (top right of photo) to allow the correct positioning of the stems walls to the full height walls.

The crawl space foundation (showing on the left with Fastfoot® installed) was already installed and braced into position. The panel C11 (two blocks high, 36") was manufactured to join the two foundations together. To accomodate the double step, the component was flipped upside down, a third block snapped into place and the fabric attached. Nudura® has locking teeth which holds the blocks together, ideal for this application.

This photo shows the same double step when filled with concrete. The contractor has bulk-headed off the form adjacent to the bank to eliminate lateral pressures.

The Fastfoot® fabric footing form serves two functions: first it allows the MP panels to adapt to uneven ground, and second, it prevents ground moisture from wicking in to the top, sides and bottom of he footing. This is essential in the wet Vancouver climate.

The pour occurred on a rainy fall morning. It was completely uneventful - which in the concrete business is a very good thing.

"I'm very pleased with the performance of the Nudura® Monopour", confirmed Brian Evans.