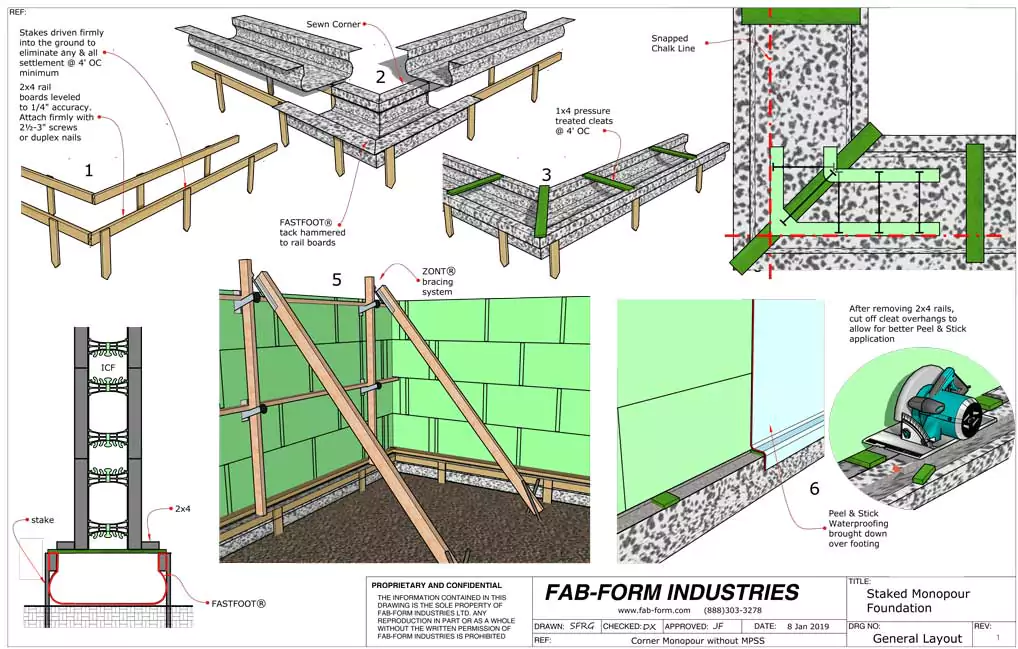

Monopour Staked System

This method allows you to pour the footing and ICF wall at one time and is ideal under the following conditions:

- Cost of delivery of concrete is very expensive;

- Cost of concrete pumping is very expensive;

- Excavation is complex with multiple steps;

- Walls greater than 10' in height;

In general, the Monopour Staked Method is always more cost effective than pouring the footing first.

The MP Side Support System (which uses side supports) is ideal for reasonably flat excavations and simpler foundation footprints with no custom corners or curved walls.

Steel reinforcing is best provided using Helix® micro rebar, reducing site labour and installation time. When doing the monopour, the foundation and footing behave as an inverted "T" beam. This can reduce the amount of steel reinforcing required (contact us for details).

This interesting project is by Nigel Protter of Exergetics, located in Pemberton BC, high in the Coast Mountains and over one hour from the nearest ready mix plant.

Advantages of Monopour Staked

This method has the following advantages over a two stage pour (footings then wall):

- Monopour is always less expensive than a two stage pour as you eliminate a pump and second concrete delivery;

- Steel reinforcing is less expensive as the footing plus wall behaves as an inverted T-beam;

- There is no cold joint, hence a stronger foundation;

- Fastfoot protects lumber and stakes from concrete damage;

- Easy stripping as Fastfoot prevents concrete contact with stakes and lumber;

In general, the Monopour Staked Method is always more cost effective than pouring the footing first.The MP Side Support System which uses the side supports is ideal for reasonably flat excavations and simpler foundation footprints (no custom corners or curved walls).

Steel reinforcing is best provided using Helix® micro rebar, reducing site labour and installation time. When doing the monopour, the foundation and footing behave as an inverted "T" beam. This can reduce the amount of steel reinforcing required (contact us for details).

Footings and walls are ready for concrete. Zont bracing has been installed.

Imagine the structural loading on the pivot joint between the truck frame and boom! Just incredible the strength of modern materials.